NTU Scientists Have Discovered A Method To Break Down Plastic Waste Using Sunlight

This method is the first in the world to break down plastic in six days.

Scientists at Nanyang Technological University (NTU), Singapore have discovered a way to turn plastics into valuable chemicals using sunlight

According to a press release, the research team, led by NTU Assistant Professor Soo Han Sen from the School of Physical and Mathematical Sciences, conducted lab experiments, mixing plastics with a catalyst in a solvent.

The resulting solution is able to harness light energy to convert the dissolved plastic into formic acid - a chemical used in fuel cells to produce electricity.

The team's catalyst was made from an affordable, non-toxic vanadium-based metal

When the catalyst was dissolved in a solution containing non-biodegradable consumer plastic and exposed to artificial sunlight, the catalyst managed to break down the plastic in just six days.

This technique is the first in the world that enables plastic to be broken down in such a short amount of time.

"This new chemical treatment is the first reported process that can completely break down a non-biodegradable plastic such as polyethylene using visible light and a catalyst that does not contain heavy metals," Soo said, as quoted by the press release.

NTU School of Physical and Mathematical Sciences Assistant Professor Soo Han Sen with the plastic-photocatalyst mixture.

Image via NTU SingaporeThe process converts plastic into formic acid

Formic acid is a naturally occurring preservative and antibacterial agent usually found in food preservatives and cleaning products.

It can also be used to generate energy in power plants and in hydrogen fuel cell vehicles such as buses and trains.

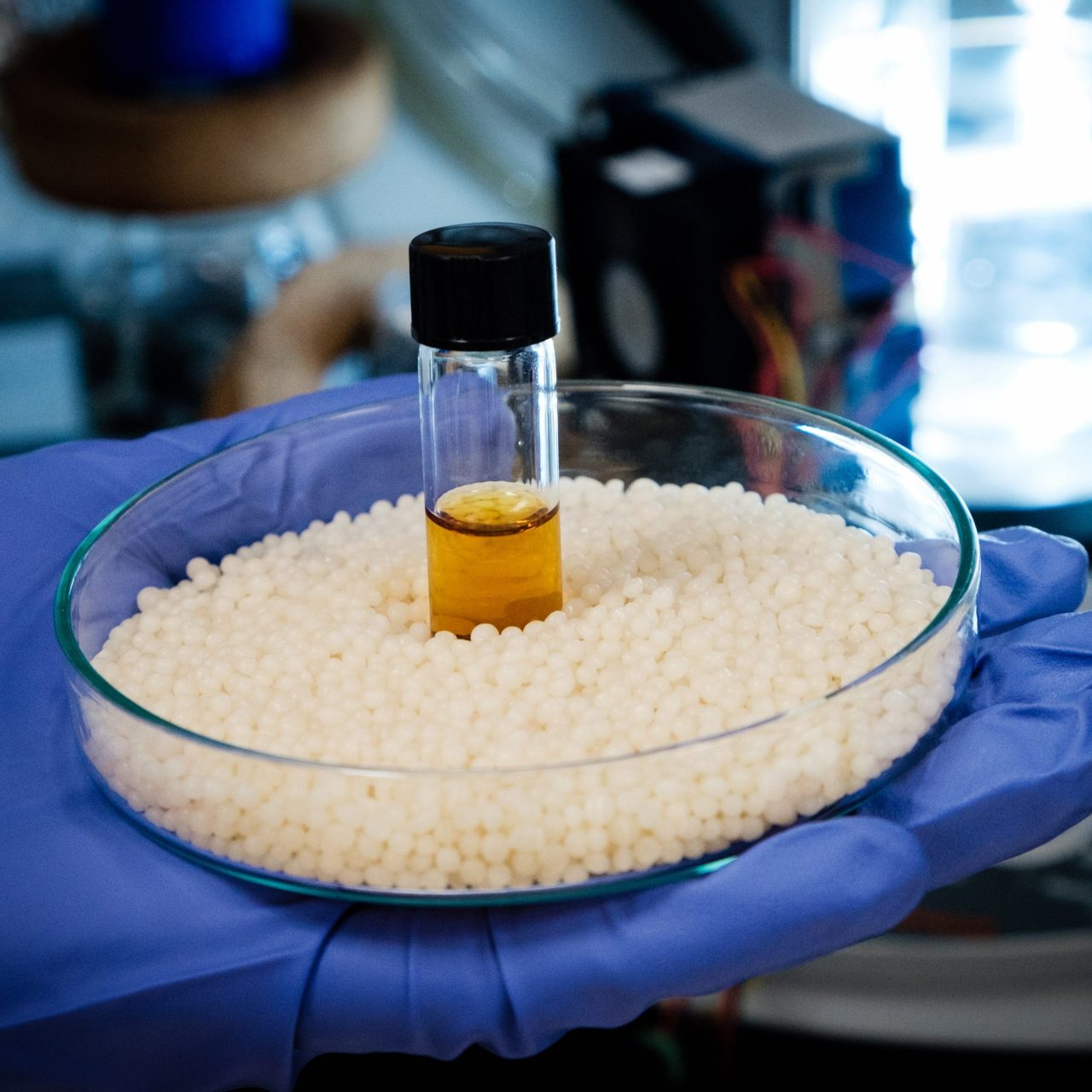

A mixture of the catalyst with dissolved plastics on a plate of plastic granules.

Image via Lester Soo/NTUAdditionally, the method is also cost effective and sustainable as it uses sunlight - a clean, free, and renewable resource

As such, this helps to reduce the carbon footprint of the technology, proving to be a more environmentally-friendly alternative to burning plastics.

Most plastic waste in Singapore gets burned, producing greenhouse gases such as carbon dioxide.

The remaining mass-burn ash will be transported to the Semakau landfill, Singapore first and only landfill, which is estimated to run out of space by 2035.

Therefore, experimenting and developing zero-waste solutions is part of the NTU Smart Campus aim to create a sustainable future.

For now, the method has a 100 percent conversion rate for non-PET plastics

In a report by Mothership, Soo said that the team is attempting to obtain research grants to attract talent and expand their work, ad the method is still at least five years away from being commercially feasible.

The following stages include seeing how the same technology can be applied to different types of plastics, as well as automating and speeding up the process.

According to Mothership, the scientists will then be testing the technology further at Pulau Semakau’s Renewable Energy Integrator Demonstrator – Singapore (REIDs) where other forms of renewable energy can be used to power or speed up the process.