How A 3D Printed Heart Model Saved A 14-Month-Old Boy's Life

The story of this 14 month-old baby is inspiring and amazing, if you pause to think about it. By thinking about other options, surgeon Erie Austin found a way, via a savvy engineering team with a MakerBot 3d printer, to save the child before he started the critical surgery.

So much has been written about the uses of 3D printing technology but its impact transcends industrial use as it is now used as a life-saving tool

Fourteen-month old Roland Lian Cung Bawi, from Owensboro, Kentucky, who was born with four congenital heart defects, had to undergo a heart surgery to fix his condition.

Heart surgery particularly on a very young child, however, can be extremely difficult and it prompted cardiothoracic surgeon Erle Austin III from Louisville, Kentucky, to turn to 3D printing technology so he can better prepare for and perform the procedure smoothly.

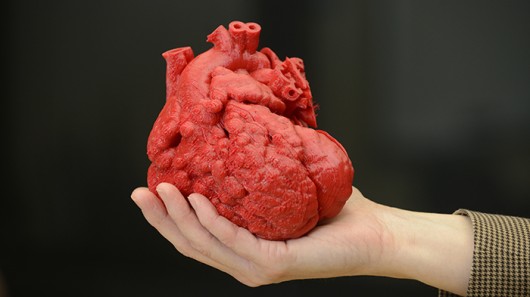

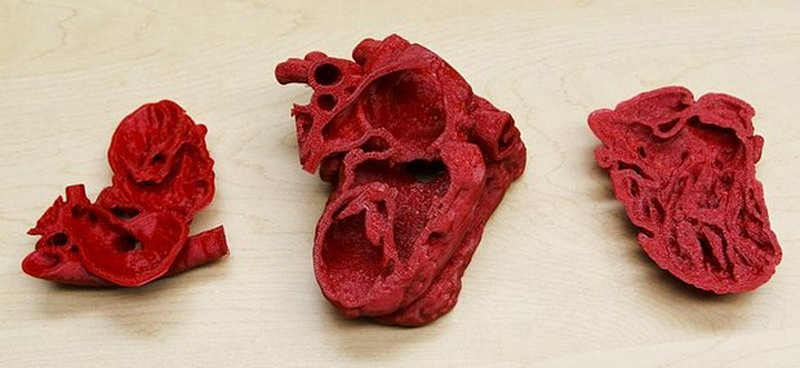

courier-journal.comUsing the facilities at the University of Louisville's engineering school, Austin and his medical team produced a 3D model of Roland's heart

Dr. Austin called the University of Louisville engineering school and they offered a MakerBot 3D Printer to create a replica model of the boy’s heart based on 2D CT scans.

policymic.comBuilt in three pieces using a flexible filament, the 3D-printed heart reportedly took around 20 hours and cost US$600

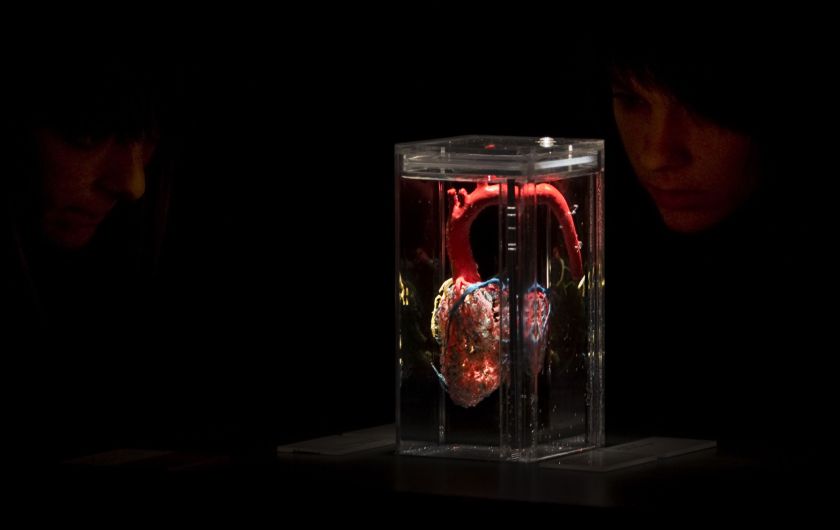

Image via gizmag.comPediatric operations are difficult because the interior structures of a child's organs are small and hard to see clearly. This model allowed the surgical team to come up with a precise plan to limit the amount of exploratory incisions, reduce operating time and prevent the need for follow-up operations.

forbes.com"Once I had a model, I knew exactly what I needed to do and how I could do it," Austin told the Louisville Courier-Journal. "It was a tremendous benefit."

The operation at Kosair Children's Hospital was declared a success, and Roland is now looking forward to a normal life expectancy.

courier-journal.comSo, how does it work?

To create the physical model, Austin asked Roland's radiologist to generate a computerized version of the boy's heart. This involved taking thousands of cross-sections of hospital X-rays and assembling them into a digital three-dimensional map.

policymic.comNext, this digitized model of the heart was used as an instructional template to feed to the engineering department's MakerBot Replicator 2X, a popular, commercially available 3-D printer model costing only $2,500.

forbes.comReading a digital template, the printer produces a thin layer of plastic, which is then built upon sequentially with other thin layer to form the three-dimensional model.

courier-journal.comThe 3-D printer assembles around 250 layers of plastic per inch of thickness. The model of Roland's heart was built two times actual size for clarity, and took around 20 hours to print, costing $600 in materials.

policymic.comAlthough hobbyists normally use a hard plastic like ABS with their MakerBot Replicators, the University of Louisville's Rapid Prototyping Center chose a flexible polymer known as "Ninja Flex"

This material is also normally used in a type of dexterous, but durable glove. This made the model's material more similar in consistency to heart muscle, a crucial detail for planning surgical incisions.

The heart was built in three separate pieces so that it could be taken apart to see the interior

"Some people think when you do heart surgery, you go in and can see everything. Well, to see everything, you have to slice through vital structures," said Austin. "Sometimes the surgeon has to guess at what's the best operation."

Austin said the model made it clear that he could create a tunneled pathway between the aortic valve and a ventricle, avoiding more cuts and multiple surgeries.

policymic.com